Product classification

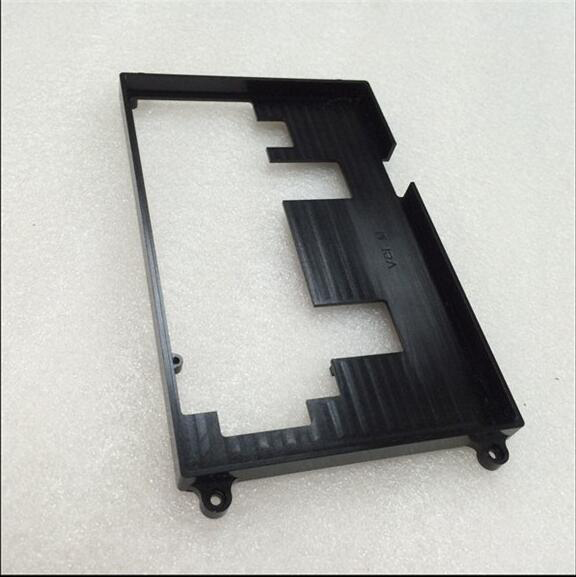

Machining Parts

-

CNC machining

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Cast alumium parts

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Brass casting

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Metal sheet

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.

-

Stamping parts

The basic knowledge of machining process of mechanical parts In the manufacturing process, due to the requirements of parts and production conditions and other different, the manufacturing process program is not the same. When the same parts are produced by different process plan, their production efficiency and economic benefit are not the same. In ensuring the quality of parts under the premise of the development of a comprehensive technical and economic benefits, a reasonable and feasible process of the process known as the part of the process design. Production process From design drawings into products, to go through a series of manufacturing process. Usually the raw material or semi-finished products into the product through the whole process is called the production process. The production process usually includes: (1) technical preparation process, including pre-production market research, forecasting, new product identification, process design, standardization review. (2) or process refers to the direct change in raw material semi-finished size, shape, surface position, surface roughness or performance, making the finished product process. Such as liquid forming, plastic deformation, welding, powder molding, cutting, heat treatment, surface treatment, assembly, etc., are all process. A reasonable process is programmed to guide the production of technical documents, the technical document known as the technical process. (3) auxiliary production process refers to the basic production process in order to ensure the normal conduct of the necessary auxiliary production activities. (4) production service process refers to the organization of raw materials, transportation, storage, storage, supply and product packaging, sales and other processes.